Supporting clients from concept design to formal mass production.

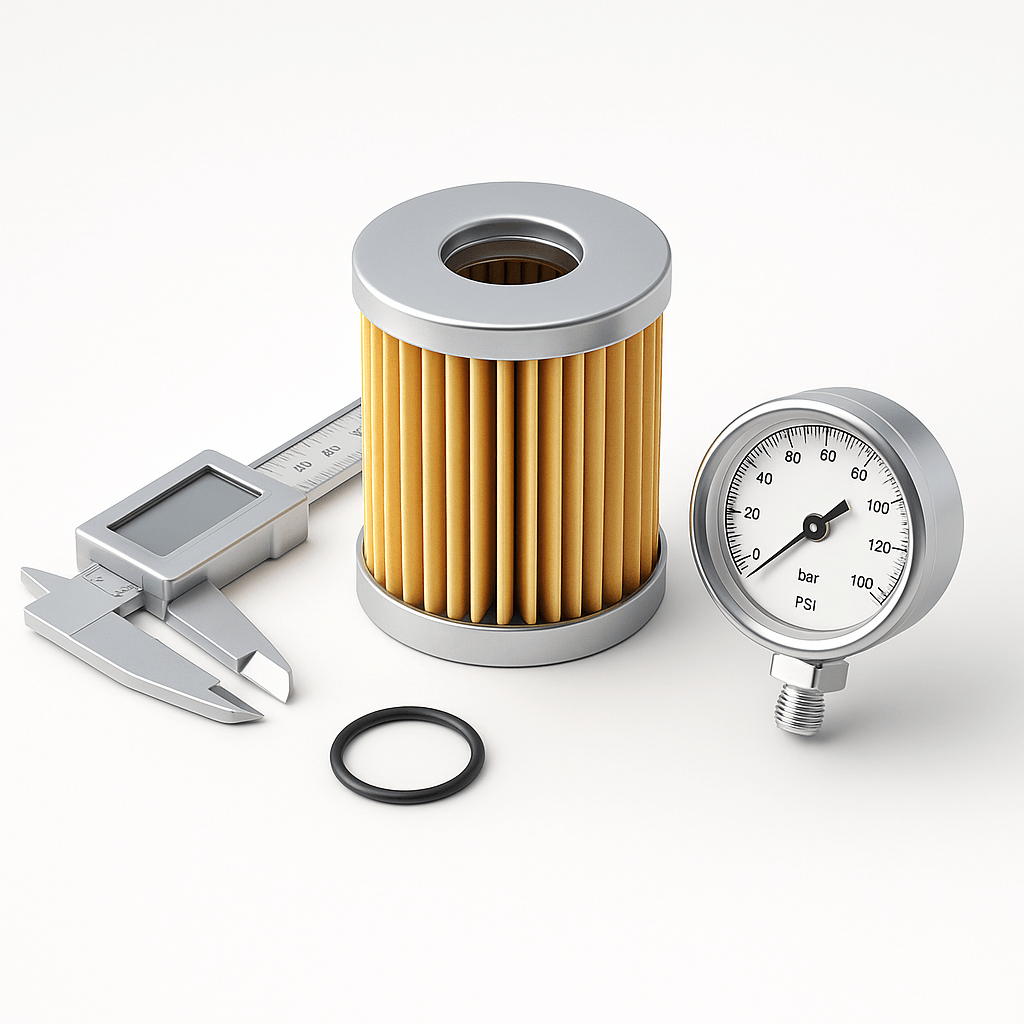

Selecting the most suitable filter media and structural configuration based on flow rate, pressure, pore size, and installation space.

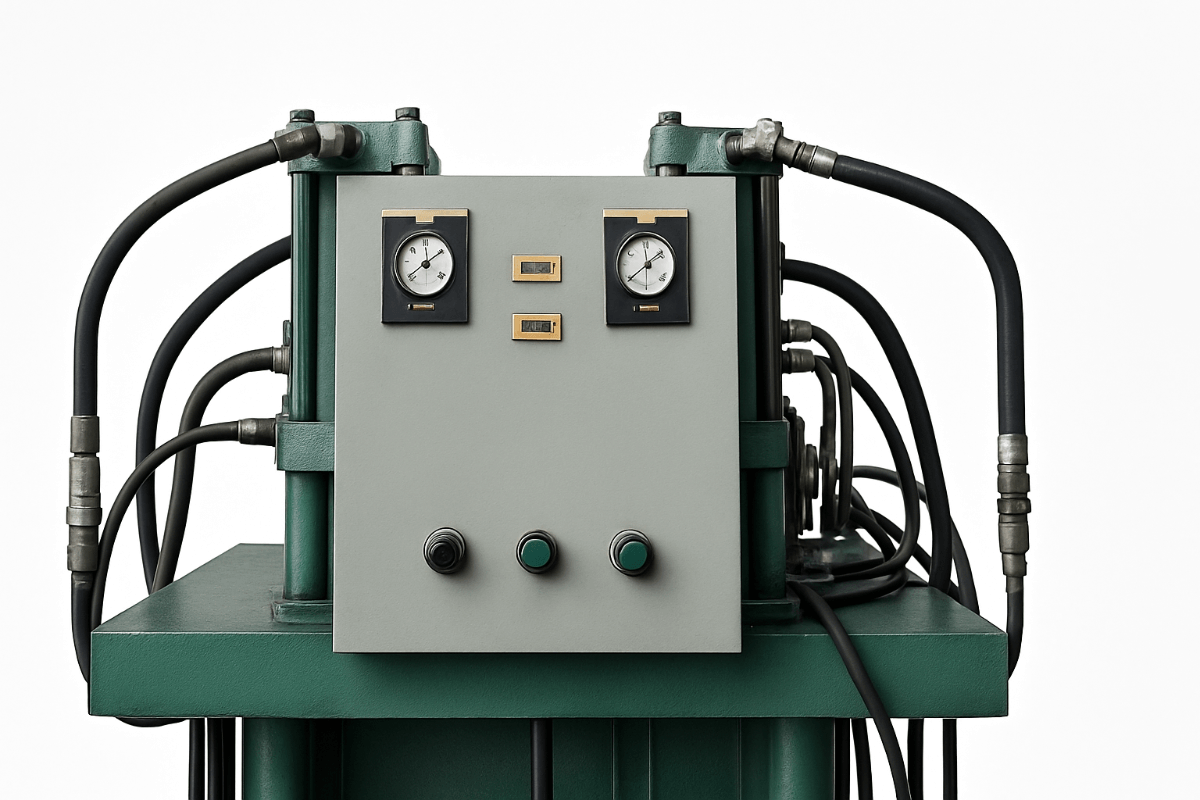

Suitable for high temperature, high pressure, and high flow rate environments / Balancing filtration efficiency and pressure drop performance.

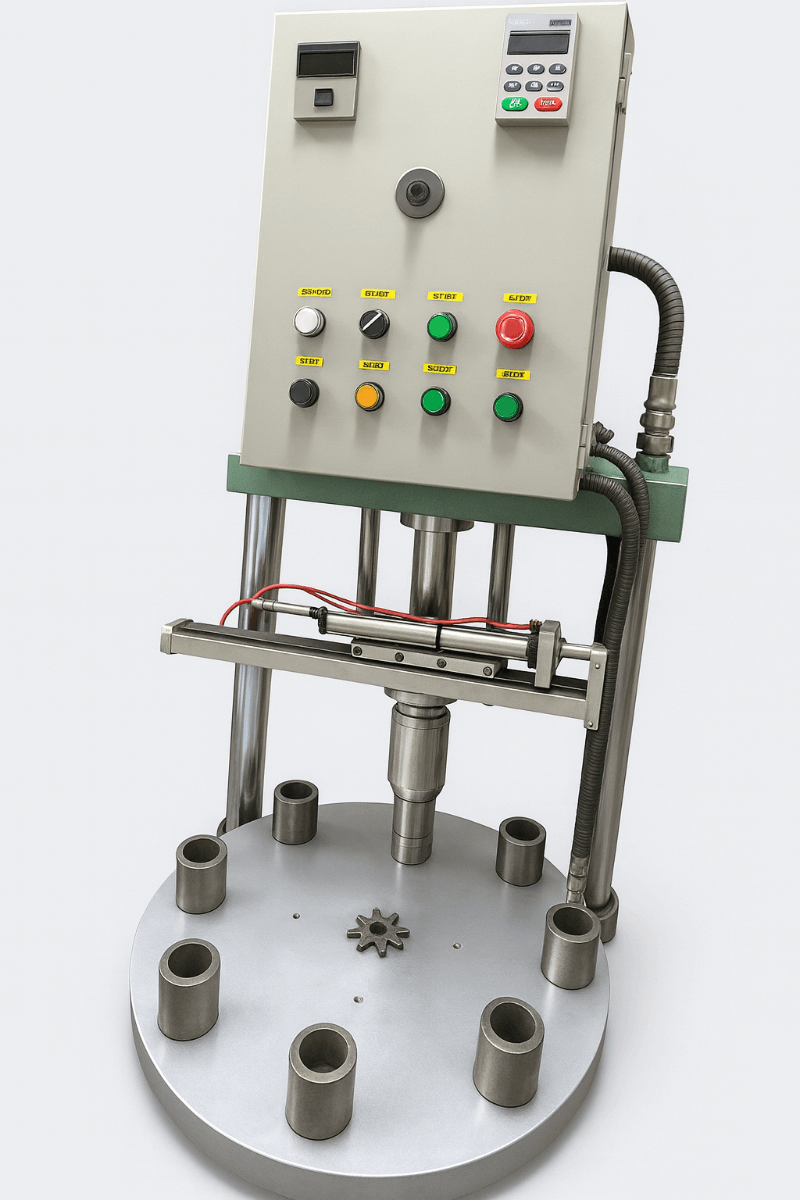

Suitable for medical equipment, precision mechanisms, and special working conditions / Enhancing safety and durability.

Supporting sample production during the R&D phase / Shortening product verification and introduction timeline.

projects by developing customized product designs and long-term supply solutions based on customer branding requirements and system specifications

From requirement analysis to mass production and delivery, every stage is strictly controlled to ensure quality and consistency.

Fluid type, flow rate, pressure, temperature, installation space, and operating conditions

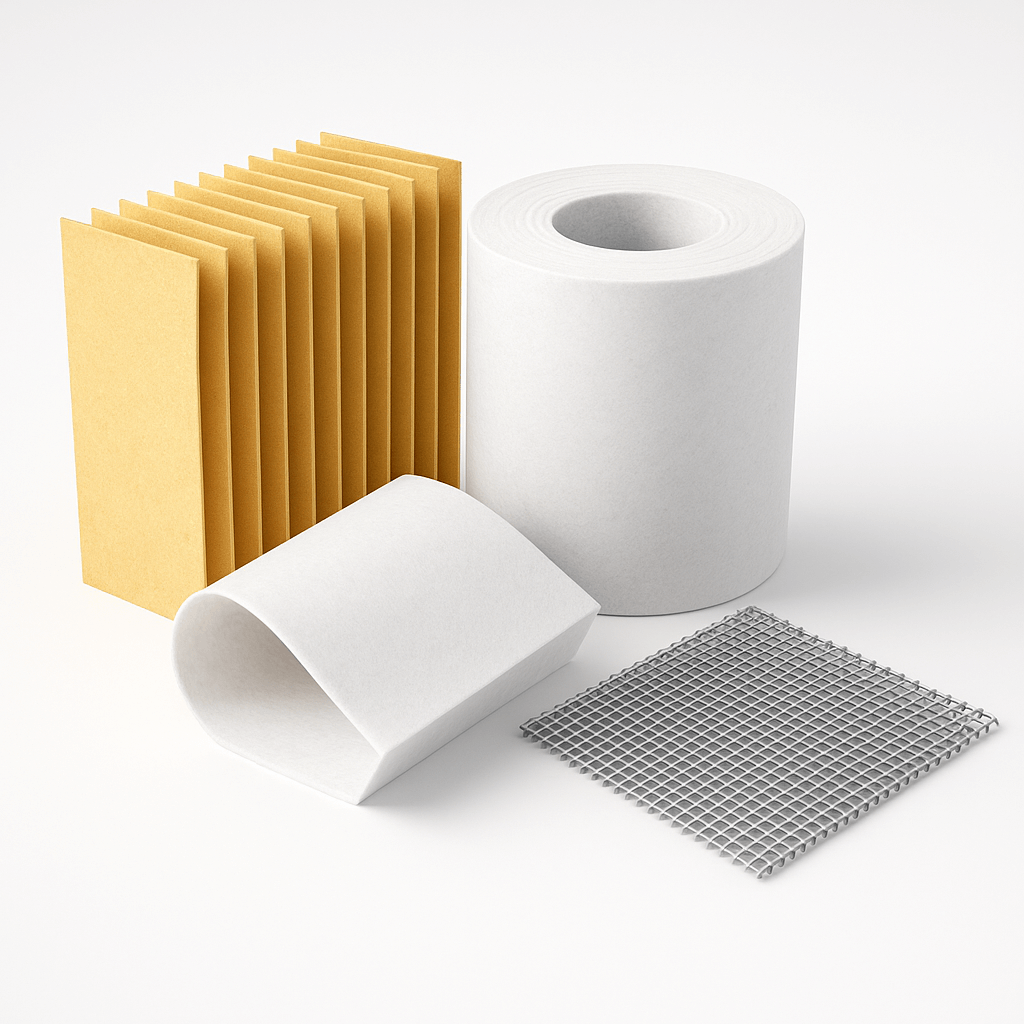

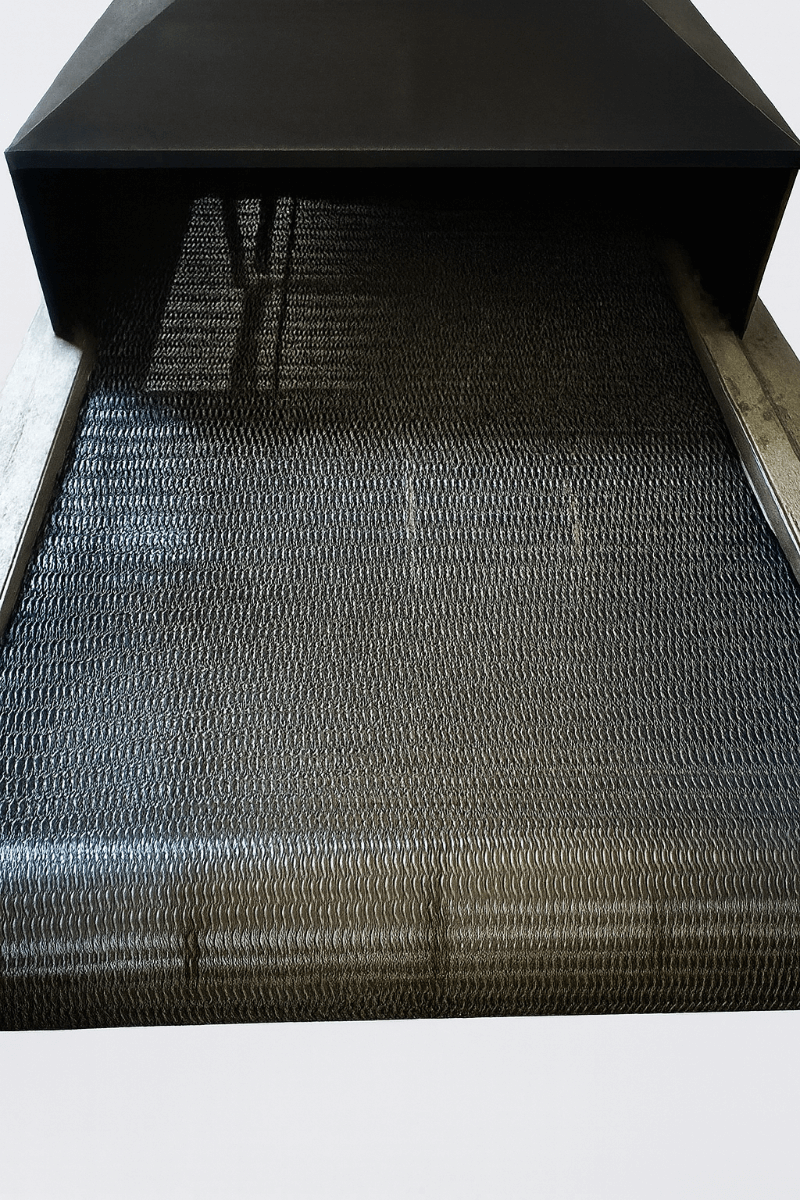

Paper, synthetic fiber, metal mesh, material properties and lifespan evaluation

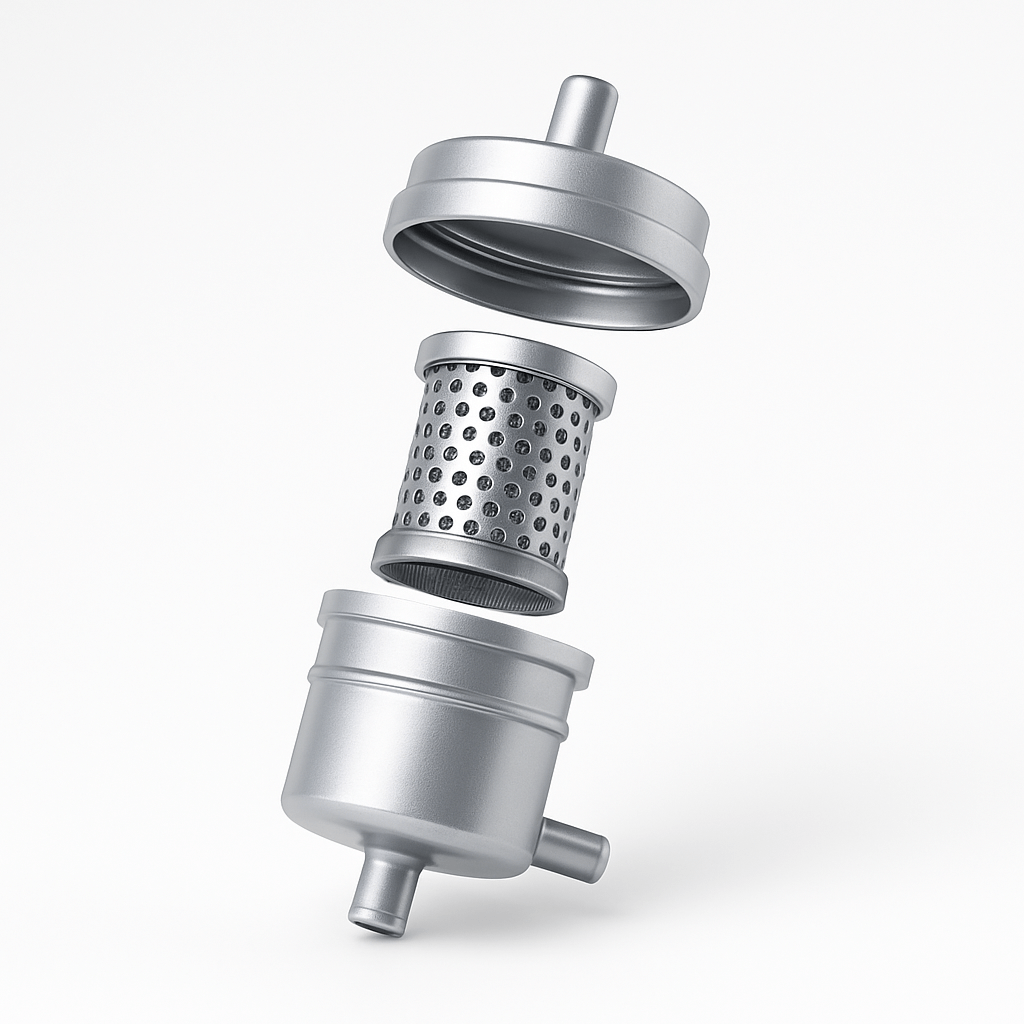

Filter shape, end cap style, sealing method and installation fit, supports multiple revisions

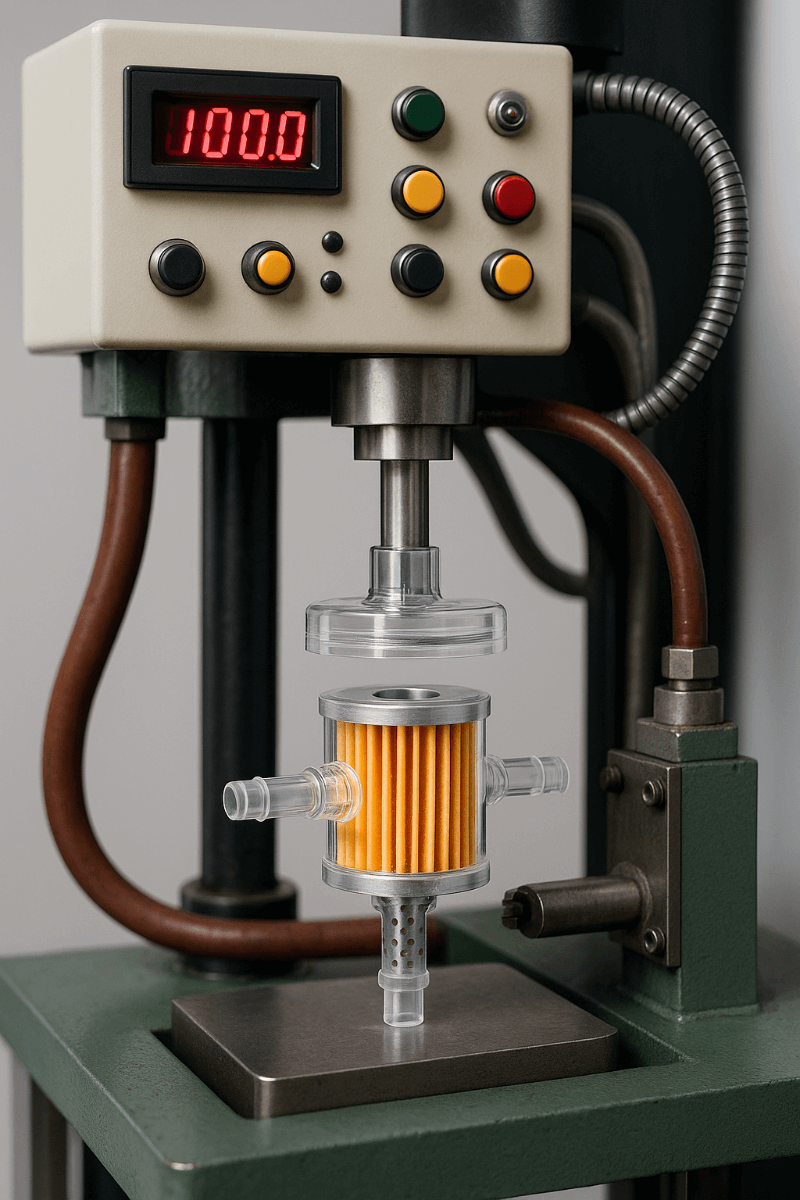

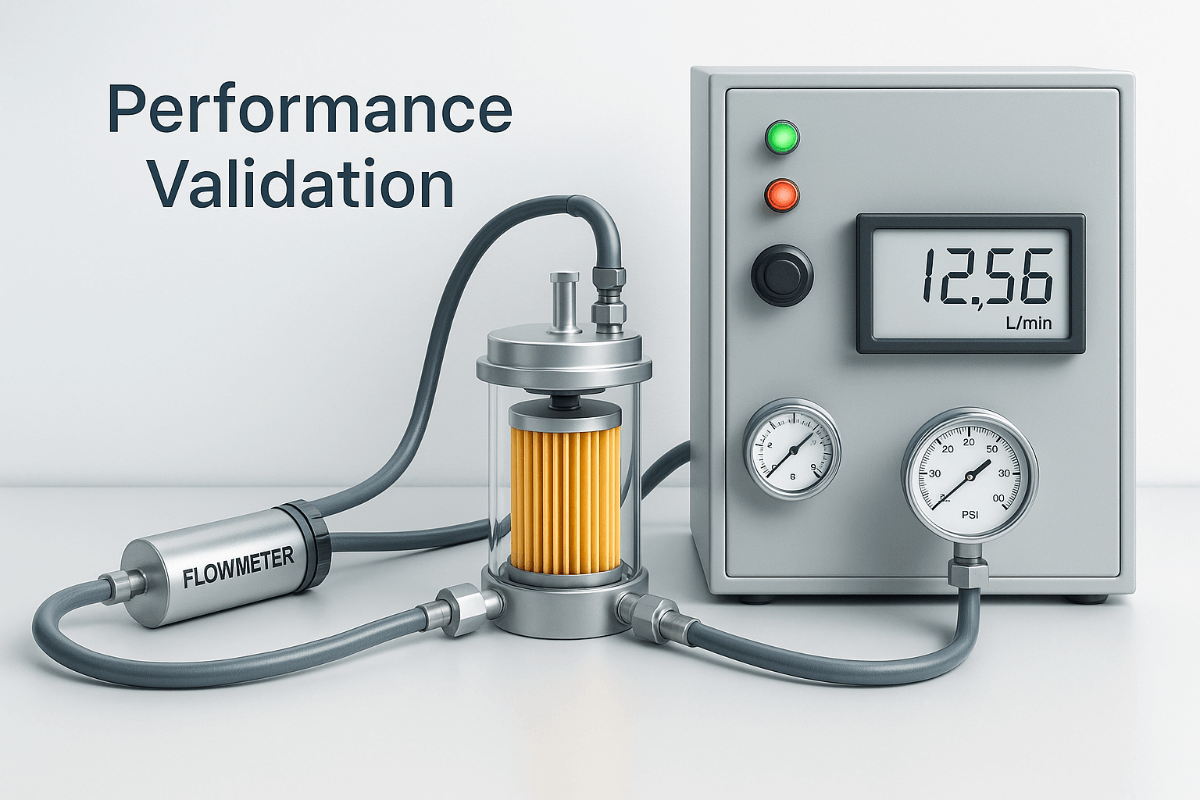

Function, pressure resistance, flow, and lifespan testing, can cooperate with third-party organizations

Functional testing is conducted according to project requirements, with optional third-party verification for performance and regulatory compliance.

Upon successful validation, the project is transferred to production lines with standardized operating procedures (SOPs) to ensure consistent quality and stable lead times.

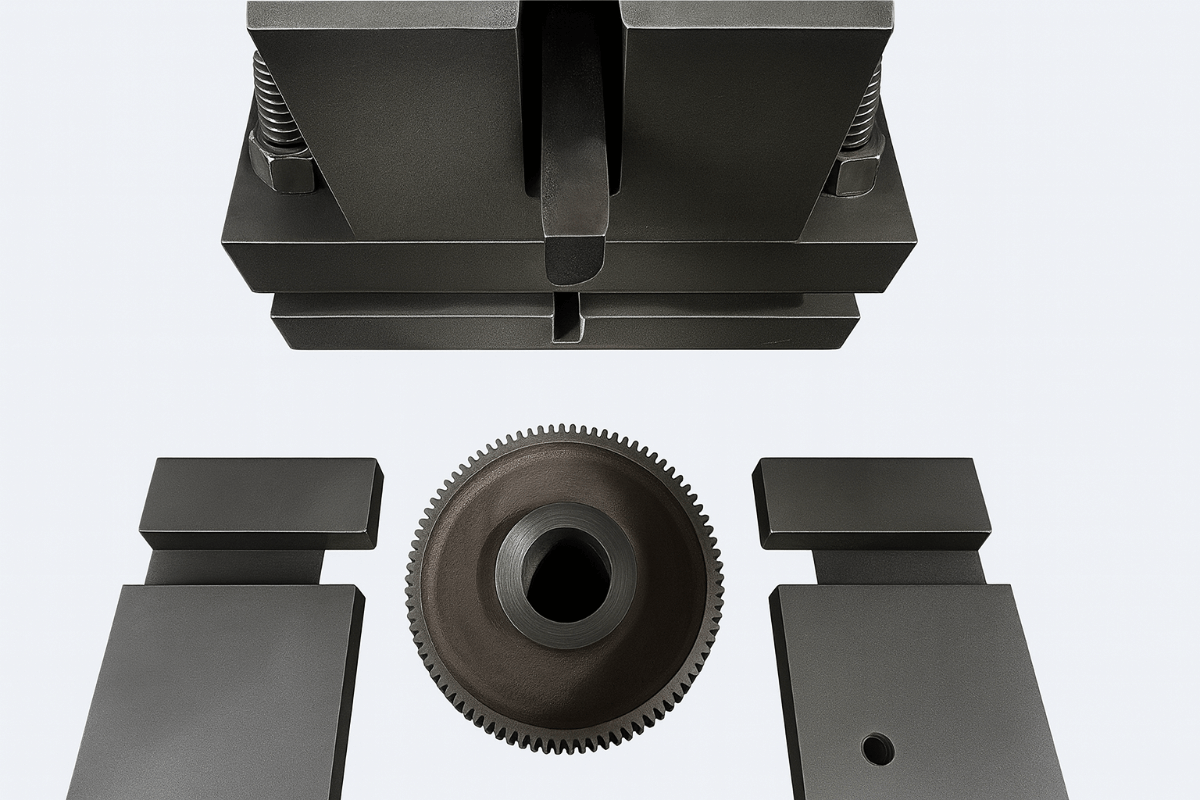

Precise control of pleat spacing and height, ensuring consistent filtration area

Trimming filter material edges, enhancing assembly precision

Used for bonding and structural curing, ensuring filter structural stability

For metal component processing

Suitable for multi-hole and high-consistency processing needs

Vibration / Rotary type, For plastic end cap and structural encapsulation

(Arranged by project)

(ISO 4020 / ISO 4548)

(REACH / RoHS)

無論是新設備導入專用濾心,或現有產品效能優化, 僑溢都能以「研發設計+自有產線+第三方驗證配合」的綜合實力, 成為您在汽機車、工具機、工業設備與醫療科技領域的長期合作夥伴。

我們會在 1–2 個工作天內 由工程團隊與您聯繫, 一起為您的設備設計最適合的濾心解決方案。